Ivalvu yeButterfly ephindwe kathathu ebekwe kwicala le-Uni

Isishwankathelo

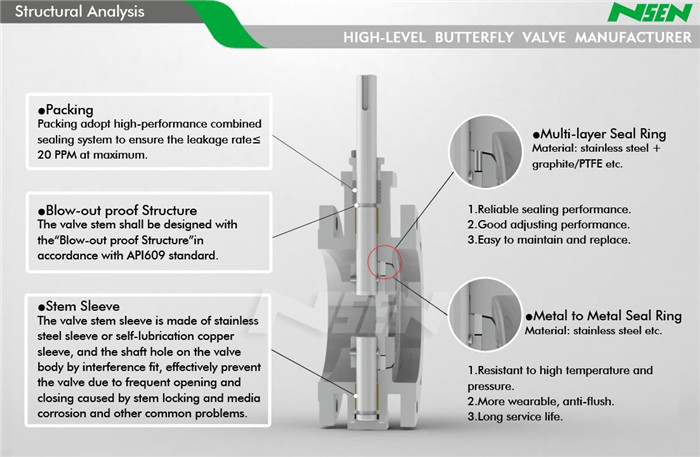

Ivalvu yebhabhathane ye-NSEN Triple offset uni-directional butterfly isebenzisa isakhiwo sokutywina esinokutshintshwa se-"Stainless steel kunye ne-graphite laminated". Olu luhlu lunokufikelela kwimfuno ye-uni-directional Zero-leakage kumgangatho ohambelanayo. Izinto zokucheba zenziwe ngentsimbi engagqwali ekumgangatho ophezulu, zinokuphepha ingxaki yokugqwala emva kokusetyenziswa ixesha elide.

• Ukuvalwa kwe-multilayer kunye nokuvalwa kwe-solid metal

• I-torque ephantsi yokuvula

• Akukho kungqubana phakathi kwesihlalo kunye nokutywinwa

• Uyilo olukhuselekileyo emlilweni oluhambelana ne-API607

• Ukuvalwa kweDiski okunokutshintshwa

Ukumakishwa kweValve:I-MSS-SP-25

Uyilo kunye noMveliso:I-API 609, EN 593

Ubukhulu Bokujongana Ubuso Nobuso:I-API 609, ISO 5752, EN 558

Uqhagamshelo Lokuphela:ASME B16.5, ASME B16.47, EN 1092, JIS B2220, GOST 12820

Uvavanyo kunye nokuhlolwa:API 598, EN 12266, ISO 5208, ANSI B16.104

Iflengi ephezulu:I-ISO 5211

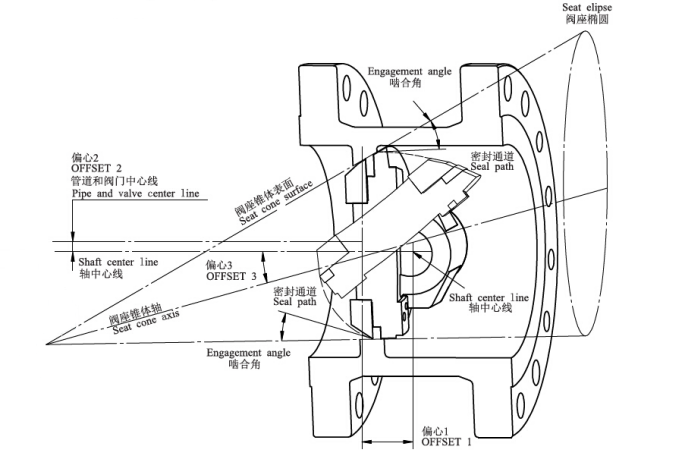

Ivalvu yebhabhathane ephindwe kathathu yongeza i-eccentric yesithathu esekwe kwisakhiwo esiphindwe kabini. I-eccentric yesithathu ine-engile ethile phakathi komgca osembindini womzimba wevalvu kunye nobuso bokutywina isihlalo esijijekileyo, iqinisekisa ukuba iringi yokutywina yediski inokwahlulwa okanye ichukunyiswe nesihlalo ngokukhawuleza ukuze ukungqubana kunye nokuxinana phakathi kwesihlalo kunye neringi yokutywina kususwe.

I-torque evulekileyo ephantsi

Olu luhlu lusebenzisa iRadial Dynamically Balanced Sealing System, ngoyilo olucwangcisiweyo, amandla asetyenziswa kumacala omabini okungena kunye nokuphuma kwediski yebhabhathane ayalingana ukuze anciphise ngempumelelo i-torque yokuvula ivalvu.

Ulwandlelizinto zeringi

Indandatho yesitywina sale serial yenziwe ngepleyiti yentsimbi engagqwaliyo enegrafiti/carbon fiber/PTFE njl. Ukuvalwa okuphambili yipleyiti yentsimbi engagqwaliyo, i-interlayer engeyiyo yesinyithi njengenye encedisayo. Olu lwakhiwo lwenza ivalvu ivalwe ngokuthembekileyo ngakumbi kwaye ukuvuza kwesitywina kufikelele kwiklasi ye-VI ukuya kwi-ANSI B16.104 okanye kwiklasi ye-A ukuya kwi-ISO 5208. Xa kuthelekiswa nezinto zepleyiti ye-asbestos zerabha, izinto zethu zokwamkela ziyanxitywa ngakumbi, azigugi, zithembekile kwaye zingcono kwindalo esingqongileyo.

Pukuxhalaba-utywino oludibeneyoinkqubo

I-NSEN yamkela olu lwakhiwo ukuqinisekisa ukuba ukuvuza kwevalvu kunokufikelela kwi-≤20ppm ubuninzi. Ulwakhiwo lokutywina oluguquguqukayo luyafumaneka ukuba kuyimfuneko, nto leyo eyenza ukutywina kokupakisha kube kwimeko elungileyo kwaye kwandise ixesha lokugcinwa kwasimahla kokupakisha.

Ulwakhiwo Oluzinzileyo Ngokulinganayo

Indandatho yokutywina yevalvu yebhabhathane iqiniswe ngeebholiti/amantongomane asasazwe ngokulinganayo. Ibholiti nganye ibekwe ngokuchanekileyo kwaye inamandla ngokulinganayo. Olu lwakhiwo lususa iingxaki zokuvuza okanye indandatho yokutywina ekhululekileyo ngenxa yamandla angalinganiyo eebholiti namantongomane.

Uyilo kunye nesakhiwo esikhuselekileyo emlilweni

Ulwakhiwo lwentsimbi oluhlala phantsi lwenza ivalvu ikhuseleke emlilweni kwaye ihlangabezana neemfuno ezikwi-API 607.

Ibhokisi yegiya

Ibhokisi yegiya yesandla enikezelwa ngomgangatho ophezulu kunye nolwakhiwo lokhuseleko, oludibene neempawu zebhokisi yegiya yophawu lwangoku eyaziwayo kunye nenqanaba lokhuseleko lifikelela kwi-IP 67.

I-NSEN ilandela ngokungqongqo iinkonzo zokulungisa zasimahla, ukutshintshwa kwasimahla kunye nokubuyiselwa kwasimahla kwiinyanga ezili-18 emva kokuba ivalvu ingasebenzi okanye iinyanga ezili-12 emva kokufakwa nokusetyenziswa kwipayipi emva kokusebenza kwangaphambili (ekuza kuqala).

Kwimeko apho ivalvu iye yawa ngenxa yengxaki yomgangatho ngexesha lokusetyenziswa kwipayipi ngexesha lewaranti yomgangatho, i-NSEN iya kubonelela ngenkonzo yewaranti yomgangatho yasimahla. Inkonzo ayizukuphela de kube ukusilela kulungisiwe kwaye ivalvu iyasebenza kwaye umthengi utyikitye ileta yokuqinisekisa.

Emva kokuphela kwexesha elichaziweyo, i-NSEN iqinisekisa ukubonelela abasebenzisi ngeenkonzo zobugcisa ezisemgangathweni ngexesha nanini na xa imveliso ifuna ukulungiswa nokugcinwa.