Ivalvu yeButterfly ephindwe kathathu enecala eliphindwe kabini

Isishwankathelo

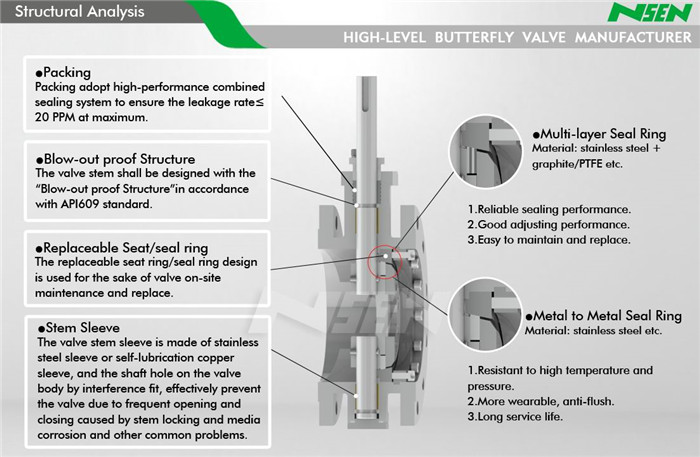

Ivalvu yebhabhathane ephindwe kathathu ye-NSEN isebenzisa isakhiwo sokutywina esinokutshintshwa se-“Stainless steel kunye ne-graphite laminated”. Oku kuqinisekisa ukusebenza okuthembekileyo kokutywina kunye nexesha elide phantsi kwemeko yokusebenza evulekileyo/evala rhoqo.

• Ukuvalwa kweeleya ezininzi

• I-torque ephantsi yokuvula

• Akukho kuvuza kuzo zombini iindlela

• Akukho kungqubana phakathi kwesihlalo kunye nokutywinwa

• Uyilo olukhuselekileyo emlilweni oluhambelana ne-API607

• Isivalo seSihlalo kunye neDiski esinokutshintshwa

Ukumakishwa kweValve:I-MSS-SP-25

Uyilo kunye noMveliso:I-API 609, EN 593

Ubukhulu Bokujongana Ubuso Nobuso:I-API 609, ISO 5752, EN 558

Uqhagamshelo Lokuphela:ASME B16.5, ASME B16.47, EN 1092, JIS B2220, GOST 12820

Uvavanyo kunye nokuhlolwa:API 598, EN 12266, ISO 5208, ANSI B16.104

Iflengi ephezulu:I-ISO 5211

Ulwakhiwo

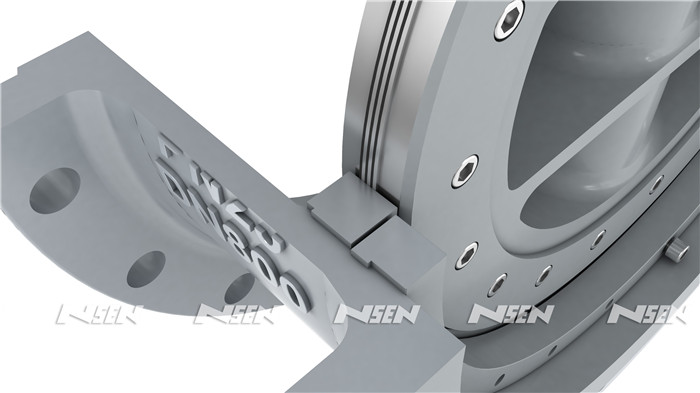

Ivalvu yebhabhathane ephindwe kathathu yongeza i-eccentric yesithathu ejikeleze i-eccentric esekwe kwisakhiwo esiphindwe kabini. I-eccentric yesithathu ine-engile ethile.

Phakathi komgca osembindini womzimba wevalvu kunye nobuso bokuvala isihlalo esijijekileyo, kuqinisekisa ukuba iringi yokutywina yediski inokwahlulwa okanye ichukunyiswe ngesihlalo ngokukhawuleza ukuze ukungqubana kunye nokuxinana phakathi kwesihlalo kunye neringi yokutywina kususwe.

Uyilo lokutywina oluhamba ngamacala amabini

Olu luhlu lunokufikelela kwimfuneko yokuvuza okungaguqukiyo kwicala ngalinye, nokuba luvavanyo lwe-hydraulic okanye uvavanyo lomoya. Uxinzelelo oluphezulu olunokufikelela kulo yi-600LB.

I-torque evulekileyo ephantsi

Olu luhlu lusebenzisa iRadial Dynamically Balanced Sealing System, ngoyilo olucwangcisiweyo, amandla asetyenziswa kumacala omabini okungena kunye nokuphuma kwediski yebhabhathane ayalingana ukuze anciphise ngempumelelo i-torque yokuvula ivalvu.

Ulwandlelizinto zeringi

Indandatho yesitywina sale serial yenziwe ngepleyiti yentsimbi engagqwaliyo enegrafiti/carbon fiber/PTFE njl. Ukuvalwa okuphambili yipleyiti yentsimbi engagqwaliyo, i-interlayer engeyiyo yesinyithi njengenye encedisayo. Olu lwakhiwo lwenza ivalvu ivalwe ngokuthembekileyo ngakumbi kwaye ukuvuza kwesitywina kufikelele kwiklasi ye-VI ukuya kwi-ANSI B16.104 okanye kwiklasi ye-A ukuya kwi-ISO 5208. Xa kuthelekiswa nezinto zepleyiti ye-asbestos zerabha, izinto zethu zokwamkela ziyanxitywa ngakumbi, azigugi, zithembekile kwaye zingcono kwindalo esingqongileyo.

Indandatho yokutywina enokutshintshwa

Iiringi zokuvala zediski kunye nesihlalo zonke zahlukile kwi-NSEN series butterfly valve, kwaye zinokutshintshwa xa kufuneka. Iringi yokuhlala yediski okanye isihlalo ingatshintshwa nganye nganye xa yaphukile, nto leyo engagcini nje ngokunciphisa iindleko zakho zokulungisa kodwa ikwanceda ukulungiswa kube lula.

Pukuxhalaba-utywino oludibeneyoinkqubo

I-NSEN yamkela olu lwakhiwo ukuqinisekisa ukuba ukuvuza kwevalvu kunokufikelela kwi-≤20ppm ubuninzi. Ulwakhiwo lokutywina oluguquguqukayo luyafumaneka ukuba kuyimfuneko, nto leyo eyenza ukutywina kokupakisha kube kwimeko elungileyo kwaye kwandise ixesha lokugcinwa kwasimahla kokupakisha.

Ulwakhiwo Oluzinzileyo Ngokulinganayo

Indandatho yokutywina yevalvu yebhabhathane iqiniswe ngeebholiti/amantongomane asasazwe ngokulinganayo. Ibholiti nganye ibekwe ngokuchanekileyo kwaye inamandla ngokulinganayo. Olu lwakhiwo lususa iingxaki zokuvuza okanye indandatho yokutywina ekhululekileyo ngenxa yamandla angalinganiyo eebholiti namantongomane.

Uyilo kunye nesakhiwo esikhuselekileyo emlilweni

Ulwakhiwo lwentsimbi oluhlala phantsi lwenza ivalvu ikhuseleke emlilweni kwaye ihlangabezana neemfuno ezikwi-API 607.

Amandla eSithili:Isikhululo samandla obushushu, isikhululo sokutshintshiselana kobushushu, isityalo sebhoyila sengingqi, iluphu yamanzi ashushu, inkqubo yepayipi yesiqu

Umatshini wokucoca:I-Brine, Umphunga we-carbon dioxide, isityalo se-propylene, inkqubo yomphunga, igesi ye-propylene, isityalo se-ethylene, isixhobo sokuqhekeka kwe-ethylene, isityalo sokucolaIsikhululo samandla enyukliya:ukwahlulwa kogcino, inkqubo yokukhupha ityuwa emanzini olwandle, inkqubo yetyuwa, inkqubo yokutshiza ephambili, ukwahlulwa kwepompo

Ukuveliswa kwamandla obushushu: ukupholisa i-condenser, ukwahlula i-pump kunye ne-steam extraction, i-heat exchanger, ukwahlukanisa i-condenser cooling, ukwahlukanisa i-pump

Ubushushu obuphantsi:igesi engamanzi, iinkqubo zegesi yendalo enyibilikisiweyo, iinkqubo zokubuyisela ioyile, izityalo zokufaka igesi kunye nezixhobo zokugcina, iinkqubo zokuthutha igesi yendalo enyibilikisiweyo

Intlama kunye nephepha:ukwahlulwa komphunga, amanzi ebhoyila, ilayimu kunye nodaka

Ukucocwa kweoyile:Ukwahlulwa kweoyile, ivalvu yokuhambisa umoya, inkqubo yokususa isalfurization kunye neprosesa yegesi emdaka, igesi yokutsha, ukwahlulwa kwegesi ye-asidi, i-FCCU

Igesi yendalo

I-NSEN ilandela ngokungqongqo iinkonzo zokulungisa zasimahla, ukutshintshwa kwasimahla kunye nokubuyiselwa kwasimahla kwiinyanga ezili-18 emva kokuba ivalvu ingasebenzi okanye iinyanga ezili-12 emva kokufakwa nokusetyenziswa kwipayipi emva kokusebenza kwangaphambili (ekuza kuqala).

Kwimeko apho ivalvu iye yawa ngenxa yengxaki yomgangatho ngexesha lokusetyenziswa kwipayipi ngexesha lewaranti yomgangatho, i-NSEN iya kubonelela ngenkonzo yewaranti yomgangatho yasimahla. Inkonzo ayizukuphela de kube ukusilela kulungisiwe kwaye ivalvu iyasebenza kwaye umthengi utyikitye ileta yokuqinisekisa.

Emva kokuphela kwexesha elichaziweyo, i-NSEN iqinisekisa ukubonelela abasebenzisi ngeenkonzo zobugcisa ezisemgangathweni ngexesha nanini na xa imveliso ifuna ukulungiswa nokugcinwa.