It has been more than 50 years since the triple eccentric butterfly valve was introduced, and it has been continuously developed over the past 50 years. The application of butterfly valves has spanned multiple industries. The original butterfly valve is only used for the interception and connection of water media. The triple eccentric design enhances the function of the butterfly valve. It has become one of the valves with excellent performance under the harshest conditions in the critical process environment in industrial industrial pipeline equipment.

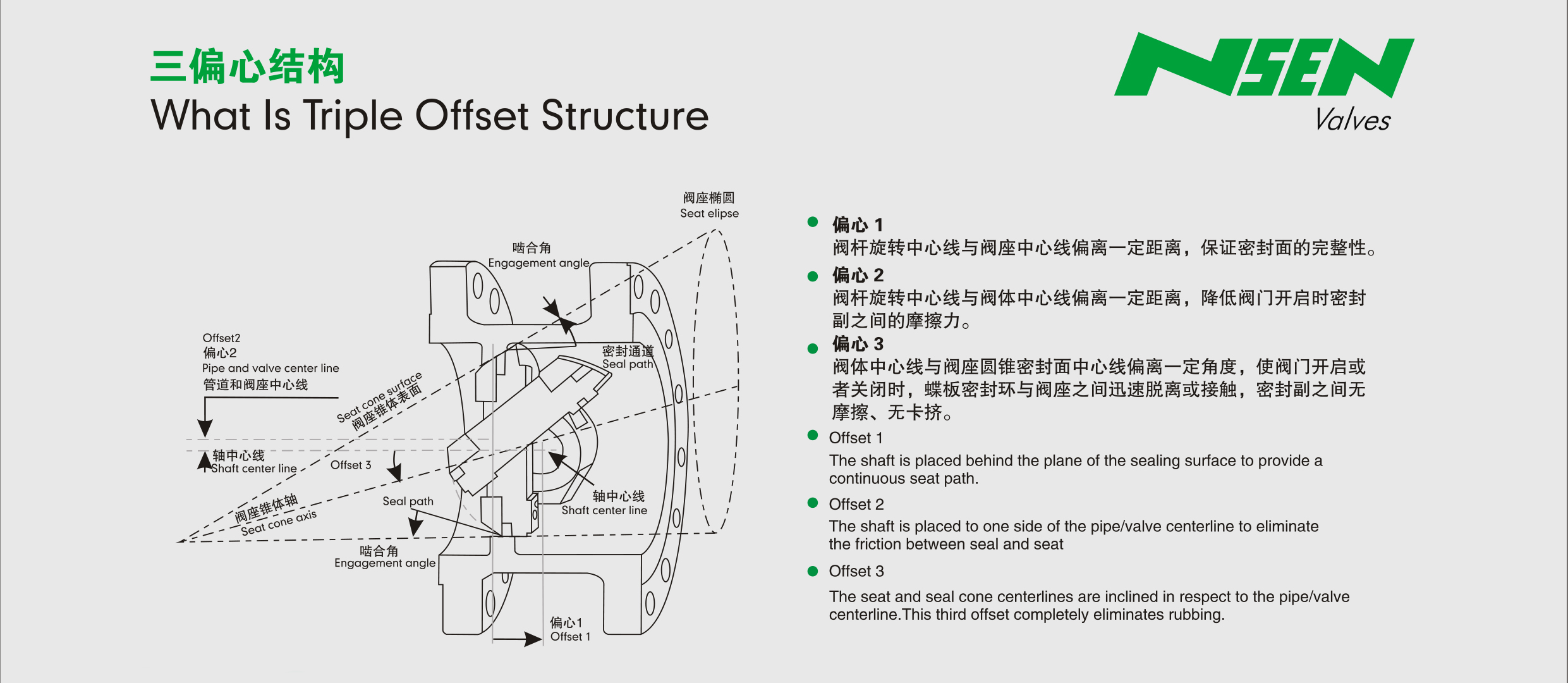

As the name suggests, three independent offsets are designed as valves. Triple eccentricity means:

- Offset 1

The shaft is placed behind the plane of the sealing surface to provide a continuous seat path.

- Offset 2

The shaft is placed to one side of the pipe/valve centerline to eliminate the friction between seal and seat

- Offset 3

The seat and seal cone centerlines are inclined in respect to the pipe/valve centerline. This third offset completely eliminates rubbing. This cone angle, along with the two eccentric shaft offsets, allows the disc to seal against the seat with no friction.

This seat design also allows for uniform sealing, and thus a tight shutoff in a metal seat design. This design is a lower cost, lower torque option (easier to automate), than alternative style metal seated valves.

Triple offsets are generally used in applications ike high pressure steam (over 150 PSI), superheated- steam, high temperature gases and oils, high temperature applications are good for this type of valve because a metal seat is required over a soft seat.

Post time: Aug-01-2020