I-valve ye-Butterfly ephindwe kathathu ebekwe eceleni kwe-Bi-directional

Ukubuka konke

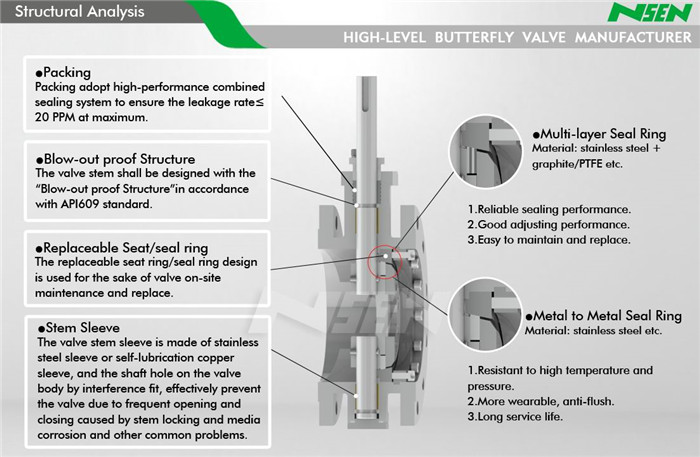

I-NSEN Triple offset Bi-directional butterfly valve isebenzisa isakhiwo sokuvala esingashintshwa se-“Stainless steel kanye ne-graphite laminated”. Lokhu kuqinisekisa ukusebenza kokuvala okuthembekile kanye nokuphila isikhathi eside ngaphansi kwesimo sokusebenza sokuvulwa/ukuvala njalo.

• Ukuvalwa kwezingqimba eziningi

• I-torque ephansi yokuvula

• Akukho ukuvuza kuzo zombili izindlela

• Akukho ukungqubuzana phakathi kwesihlalo nokuvala

• Umklamo wokuvikela umlilo ku-API607

• Ukuvalwa Kwesihlalo Nediski Okungashintshwa

Ukumaka Amavalvu:I-MSS-SP-25

Ukuklama Nokukhiqiza:I-API 609, EN 593

Ubukhulu Bokubukana Ubuso Nobuso:I-API 609, ISO 5752, EN 558

Ukuxhumana Okuphelile:ASME B16.5, ASME B16.47, EN 1092, JIS B2220, GOST 12820

Ukuhlolwa Nokuhlolwa:I-API 598, EN 12266, ISO 5208, ANSI B16.104

I-Flange Ephezulu:I-ISO 5211

Isakhiwo

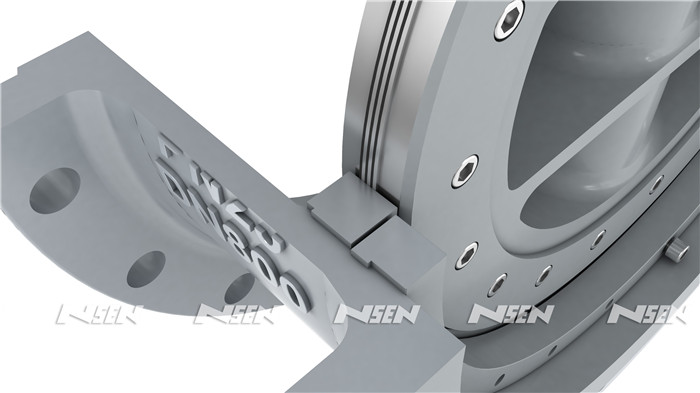

Ivalvu yebhabhathane eliphindwe kathathu lifaka i-eccentric yesithathu e-angle esekelwe kwisakhiwo esiphindwe kabili. I-offset yesithathu ihlanganisa i-engeli ethile.

Njengoba iphakathi komugqa ophakathi womzimba we-valve kanye nobuso bokuvala isihlalo obuyindilinga, iqinisekisa ukuthi indandatho yokuvala yediski ingahlukaniswa noma ithintwe ngesihlalo ngokushesha ukuze ukungqubuzana kanye nokucindezelana phakathi kwesihlalo nendandatho yokuvala kuqedwe.

Umklamo wokuvala oqondene nezinhlangothi ezimbili

Lolu chungechunge lungafinyelela isidingo se-Zero-leakage esiqondiswe ohlangothini olubili ngokwezinga elihlobene, kungakhathalekile ukuhlolwa kwe-hydraulic noma ukuhlolwa komoya. Umfutho ophezulu kakhulu ongafinyelela kuwo ungama-600LB.

I-torque ephansi yokuvula

Lolu chungechunge lusebenzisa i-Radial Dynamically Balanced Sealing System, ngomklamo olungiselelwe kahle, amandla asetshenziswa kuzo zombili izinhlangothi ukuze kungene i-butterfly disc kanye ne-outlet alingane kahle ukuze kwehliswe ngempumelelo i-torque yokuvula i-valve.

Ulwandlelizinto zendandatho

Indandatho yokuvala yalolu hlobo lwe-serial yenziwe ngepuleti lensimbi engagqwali ene-graphite/carbon fiber/PTFE njll. Ukuvala okuyinhloko yipuleti lensimbi engagqwali, i-interlayer engeyona eyensimbi njengeyomsizi. Lesi sakhiwo senza i-valve ivalwe ngokwethembeka futhi ukuvuza kokuvala kufinyelele ekilasini le-VI ku-ANSI B16.104 noma ekilasini le-A ku-ISO 5208. Uma kuqhathaniswa nezinto zepuleti le-asbestos ngerabha, izinto zethu zokwamukela ziyagqokwa kalula, azishisi, zithembekile futhi zingcono kakhulu kwezemvelo.

Indandatho yokuvala engashintshaniswayo

Izindandatho zokuvala zediski nesihlalo zonke zihlukile ze-NSEN series butterfly valve, futhi zingashintshwa uma kudingeka. Indandatho yokuhlala yediski noma isihlalo ingashintshwa ngayinye uma iphukile okungehlisi nje izindleko zakho zokulungisa kodwa futhi kwenza ukulungiswa kube lula.

Pukucasuka-ukuvalwa okuhlanganisiweuhlelo

I-NSEN yamukela lesi sakhiwo ukuqinisekisa ukuthi ukuvuza kwe-valve kungafinyelela ku-≤20ppm ngobuningi. Isakhiwo sokuvala esiguquguqukayo siyatholakala uma kudingeka, okwenza ukuvala kokupakisha kube sesimweni esihle futhi kwandise isikhathi sokulungisa samahhala sokupakisha.

Isakhiwo Esiqinile Ngokulinganayo

Indandatho yokuvala yevalvu yebhabhathane iqiniswe ngamabholidi/amantongomane asakazwe ngokulinganayo. Ibholidi ngalinye lisendaweni efanele futhi libekezelela amandla ngokulinganayo. Lesi sakhiwo siqeda izinkinga zokuvuza noma indandatho yokuvala ekhululekile ngenxa yamandla angalingani amabholidi namantongomane.

Umklamo kanye nesakhiwo esiphephile emlilweni

Isakhiwo esihlala ngensimbi senza i-valve ivikeleke emlilweni futhi ihlangabezane nesidingo ku-API 607.

Amandla esifunda:Isiteshi sikagesi esishisayo, isiteshi sokushintshanisa ukushisa, isitshalo sebhoyila sesifunda, iluphu yamanzi ashisayo, uhlelo lwepayipi eliyisisekelo

Indawo yokuhluza:I-Brine, Umhwamuko we-Carbon dioxide, isitshalo se-propylene, uhlelo lomhwamuko, igesi ye-propylene, isitshalo se-ethylene, idivayisi yokuqhekeka kwe-ethylene, isitshalo sokuphehlaIsikhungo samandla enuzi:ukuhlukaniswa kokuqukethwe, uhlelo lokukhipha usawoti emanzini olwandle, uhlelo lwe-brine, uhlelo lokufafaza oluyinhloko, ukuhlukaniswa kwephampu

Ukukhiqizwa kwamandla okushisa: ukupholisa i-condenser, ukuhlukaniswa kwephampu kanye nokukhishwa komusi, i-heat exchanger, ukuhlukaniswa kokupholisa i-condenser, ukuhlukaniswa kwephampu

Izinga lokushisa eliphansi:igesi ewuketshezi, izinhlelo zegesi yemvelo encibilikisiwe, izinhlelo zokubuyisa insimu kawoyela, izitshalo zokufaka igesi kanye nemishini yokugcina, izinhlelo zokuthutha igesi yemvelo encibilikisiwe

I-Pulp nephepha:ukuhlukaniswa komusi, amanzi abilayo, ilayisi nodaka

Ukuhluzwa kwamafutha:Ukuhlukaniswa kwesitoreji sikawoyela, i-valve yokuhambisa umoya, uhlelo lokususa i-sulfurization kanye neprosesa yegesi elahliwe, igesi evuthayo, ukuhlukaniswa kwegesi ye-asidi, i-FCCU

Igesi yemvelo

I-NSEN ilandela ngokuqinile ukulungiswa kwamahhala, ukushintshwa kwamahhala kanye nezinsizakalo zokubuyiselwa kwamahhala zingakapheli izinyanga eziyi-18 ngemuva kokuthi ivalvu isisebenzile noma izinyanga eziyi-12 ngemuva kokufakwa nokusetshenziswa epayipini ngemuva kokusebenza kwangaphambilini (okuzofika kuqala).

Uma kwenzeka ivalvu yehluleka ngenxa yenkinga yekhwalithi ngesikhathi sokusetshenziswa epayipini ngaphakathi kwesikhathi sewaranti yekhwalithi, i-NSEN izohlinzeka ngensizakalo yewaranti yekhwalithi yamahhala. Insizakalo ngeke iphele kuze kube yilapho ukwehluleka sekulungisiwe futhi ivalvu ivame ukusebenza futhi iklayenti lisayina incwadi yokuqinisekisa.

Ngemva kokuphela kwesikhathi esishiwo, i-NSEN iqinisekisa ukuhlinzeka abasebenzisi ngezinsizakalo zobuchwepheshe ezisezingeni eliphezulu ngesikhathi noma nini lapho umkhiqizo udinga ukulungiswa nokunakekelwa.