Since the implementation of the 6S management policy by NSEN, we has been actively implementing and improving the details of the workshop, aiming to create a clean and standardized production workshop and improve production efficiency.

This month, NSEN will focus on “safe production” and “equipment inspection and maintenance”.

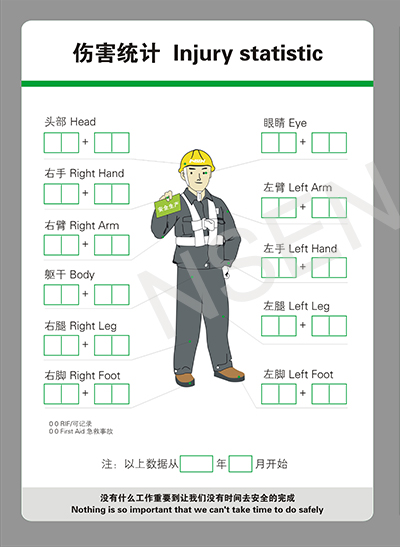

In order to enhance employees’ awareness of production safety, a safety information board is specially added. In addition, the factory will organize regular safety production training.

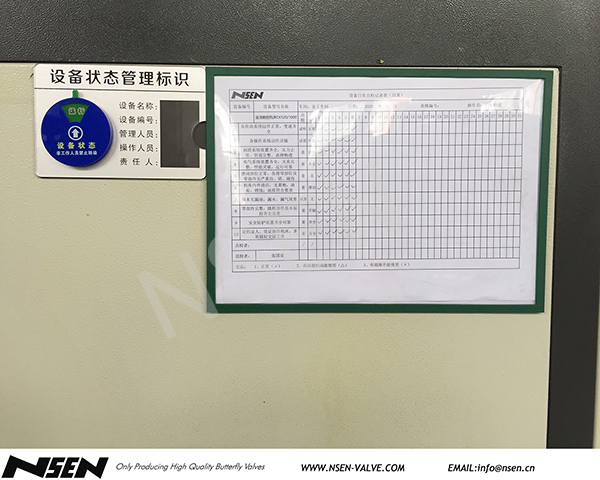

The equipment management mark is newly added, that require the operating staff regularly check the existing equipment every day. If the equipment is in good condition and the left pointer points to the green operating status. This is in order to be able to find and solve as soon as possible in the case of equipment failure. At the same time, it is to ensure that employees can work safely.

The workshop is divided into sections, and the relevant person in charge shall guide the product quality and production safety, and conduct an assessment once a month. Recognize and encourage outstanding employees, and educate backward individuals.

In order to bring more satisfactory customer service and high quality butterfly valve, NSEN has been working hard.

Post time: Sep-11-2020